Description

The Wilson Stainless steel Bushing Type Full Length Sizing Die. (Choose neck bushings separately)

- This die will allow you to full length resize the case body and shoulder, at the same time size the neck to your desired neck tension using interchangeable Wilson neck bushings.

- Bushing sold separately. Interchangeable Bushings to get the desired Neck Tension for bullet grip. (Also dependent of brass wall thickness.)

- Bushing height within the die can separately be adjusted to decide how far down the case neck the resizing is done.

- Die includes an adjustable depth decapping rod. Extra De-Capping Punch also included,

- Does not use an expander. (See important note below)

- Made of High Quality Heat Treated Steel – Hardened to L.E. Wilson Specifications. Harder than a Grade 8 Bolt

- Fits Standard 7/8ths Reloading Press

- Sizes cartridge case shoulder and body dimensions. As with all FL sizing dies these should be setup in the reloading press to minimal shoulder bump (-0.002″)

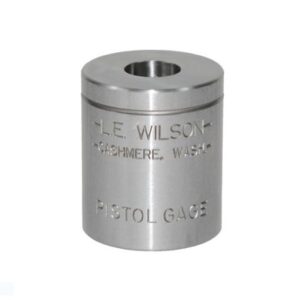

- Use with your L.E. Wilson Case Gage to Determine Proper Sizing and to Prevent Overworking your Brass

- Stainless Parts for a Long Lasting Finish Durable and Accurate

- L.E. Wilson manufactured lock nut – thickness is .225″ from inside to outermost edge .270″ for height and 1.250″ total width OD. Please note, these die will work perfectly in a Forster CoAx reloading press, but as with any dies used in that system you will need to use a Forster Crossbolt lock ring to fit with the Forster press.

TIP: Important to know.

Notes about inside case neck expanding.

As with nearly all the types of resizing dies which use the interchangeable neck size bushings system (like these), there is NO expander system on the decapping rod of the die. This is on purpose.

These are intended for, and ideally used together with cartridge cases which have been outside neck turned (machining) to uniform the brass wall thickness. When done, an internal expander is therefore not required.

But, when using dies like these with cartridges cases which are NOT outside neck turned, the wall thickness will vary of course. Therefore this means internal diameter variations will occur after sizing. This translates to variations in bullet grip (neck tension). Therefore to even out the inside size a special expander system would be needed and used separately. But, how much expanding is needed depends on brass wall thickness and variation. We recommend you check out our KM Shooting Custom special undersize expander system if you intend to use this type of die without outside neck-turning the brass.

NB: Inside expanding is not a perfect system either, but could be better than nothing. Certainly for best results we recommend outside neck turning to uniform wall thickness of the brass.

2nd note: We are disappointed to have to say this, but if you will be using Hornady brass in either 6mm or 6.5 Creedmoor with these dies (in fact any Neck bushing type FL die) and then expect you can use an expander system to help overcome the irregular effects of this brass, you will be disappointed and frustrated for sure. We feel forced to mention this because we have had to deal with some many reloading problems which some customers are having after buying lots of nice dies and other nice tools like this and get poor results. It’s all because of poor brass. The brass might look good externally but it has very high springback and is particularly tight in the shoulder/neck junction area. No expander will correct it. Bullet seating will be irregular and inconsistent and some bullets (particularly Hornady ELD’s etc) and will show compression rings where the seater stem contacts. If you wish to do a some precision reloading and precision shooting…BUY GOOD BRASS is our advice from lots of experience.

7mm08, 7-08, 22PPC, 6x47Lap, 6mmx47, 6BRNorma, 6mmBR, 6dasher, 6mmDasher, 6.5×55, 6.5 x 55Swedish, 300RSAUM, 7mmRSAUM, 300rem ultra, 6PPC factory, 6mmPPC, 6PPC, 6×45, 6mmx45, 6XC, 6XC T, 6XC Tubb, 6mm ARC, 22BR, 22-250, 222rem, 223rem, 243Win, 6BR, 6BR match, 6mmBR, 6PPC, 6BRA, 6mmBRA, 6BRX, 6mmBRX, 6mm Creedmoor, 6Creedmoor, 25-06, 260Rem, 6.5×284, 6.5x47Lap, 6.5Creedmoor, 6.5PRC, 270win, 6XC, 7BR, 7mmBR, 7mmRem Mag, 7 rem mag, 7RM, 7MM WSM, 7WSM, 280rem, 284win, 30-06, 30BR, 300Blackout, 300AAC, 338Lap, 300win mag, 300WSM, 300PRC, 308win, 6GT