Description

Forster Bench Rest Seater Dies

Forster created the first die of its kind on the market, and it’s still the best straight-line Seater Die anywhere. The sliding Die Chamber has a concentric bullet channel just slightly larger than the bullet diameter. This tight fit ensures straight-line (co-axial) seating.

The hand-polished Bullet Seating Stem provides consistent reloads. The Seater Die adapts to most standard reloading presses. Its non-crimping style provides accuracy, consistency, and perfect alignment.

Years ago, Forster/Bonanza obtained U.S. Patent #3,440,923 for the design of the original Bench Rest Seater Die. That patent covered the use of a specially machined, close-fitting chamber that holds the case, the bullet, and the seating stem all in perfect alignment. This innovative chamber design is still the hallmark of our Bench Rest Seater Dies, because it’s the premier system of all “in-line” seater systems, which support the entire outside diameter of the sized case rather than just the bullet and case neck.

We have continued to refine our seating stems to better fit newly designed ballistic tips and to match most very low drag (VLD) bullets. Our close-fitting chamber (part #P-30) made with one-piece reamers ensures concentricity and accuracy.

Seater Dies are available in 80 calibers, either individually or bundled with a Full Length Sizing Die in a set.

*Video – setting up BR seater up in Cox-ax press

Stuart’s Notes: fair warning.

We are disappointed to have to say this, but if you will be using Hornady brass for either 6mm or 6.5 Creedmoor with any good dies (not only these Forster dies) and then expect that an internal neck expander resizing system will help overcome the irregular effects of this brass, you will be disappointed and frustrated for sure. We feel forced to mention this because we have had to deal with some many reloading problems and complaints which some customers are having. After buying lots of nice dies and other nice tools like these Forster seaters (or LE Wilson seaters) and get poor results. It’s all because of poor brass. The brass might look good externally but it has very high springback and is particularly tight down in the shoulder/neck junction area. No expander will correct it. It does vary but mostly just springs back to where it was before and the reloaders don’t figure out this out. It is difficult to measure and observe. Bullet seating will be irregular and inconsistent and worse with some bullets (particularly if also using Hornady ELD type bullets). Often will show compression rings where the seater stem contacts (and slips) if bullets are seated deep for sure. There are many other things too which can impact bullet seating tension and pressure, like proper inside case lube. But our advise is, if you wish to do a some precision reloading and precision shooting…BUY GOOD BRASS. That is is our recommendation from lots of experience. Please don’t blame the tools being used, when diagnosing issues like this, look closely at the components being used first.

Troubleshooting bullet seating

Click this link below to download a PDF by Forster Products

Troubleshooting Bullet Seating

On another subject: Die position within the reloading press here is Stuarts’ tip,

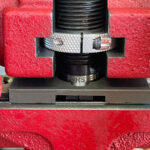

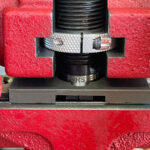

I like to illustrate and describe the correct setup position of the Forster Ultra die within the reloading press a little differently to that in the instructions sheet supplied by Forster Products. I like to call this a sort of “double check”. Because This is a visual thing. I will use a ‘Sharpie’ pen to draw a temporary line on the sliding sleeve of these dies. Just above the engraved word FORSTER. You can see this is the pictures below. Then I insert the die into the press (any reloading press) and adjust the die height so that when the ram with a shellholder, or as in these pictures, the Forster Coax press shellplate pushes the die cartridge sleeve up into the die at full extension then this ‘sharpie line’ line is just covered, yet the full amount of the engraved word FORSTER is still visible. The result is the sleeve pushes into the die body about 1/2 of the total travel and that is the correct position to have it.

If it travels into the body too far there is high risk that the bullet seating stem up in the die can move down out of its support area and the thin end could flare out with high bullet seating pressure. On the other hand if not wound down far enough there will be trouble gaining seating stem adjustment. So once this is achieved that is the lock up position and leave your lock rings set at that so you can repeat settings in future reloading sessions.